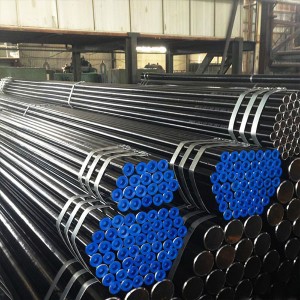

Ọkpụrụkpụ Wall Alloy Tube

Alloy pipes nwere akụkụ oghere ma jiri ya mee ihe n'ọtụtụ dị ka pipeline maka ibufe mmiri mmiri, dị ka pipeline maka ibufe mmanụ, gas, gas, mmiri na ụfọdụ ihe siri ike. E jiri ya tụnyere ígwè siri ike dị ka gburugburu nchara, alloy steel pipe dị ọkụ mgbe ike na-ehulata na torsion bụ otu. Alloy ígwè ọkpọkọ bụ ụdị echekwa cross-ngalaba ígwè, nke ọtụtụ-eji na mmepụta nke structural akụkụ na n'ibu akụkụ, dị ka mmanụ akuakuzinwo ọkpọkọ na ụgbọala nnyefe. Axes, okpokolo agba igwe na nchara nchara eji eme ihe owuwu ụlọ, wdg. Ojiji nke ọkpọkọ ọla edo na-emepụta akụkụ mgbanaka nwere ike ịbawanye ọnụego ojiji nke ihe, mee ka usoro nrụpụta dị mfe, chekwaa ihe na nhazi oge mmadụ, dị ka mgbanaka na-agbagharị agbagharị. , akwa jaket, wdg, nke ejirila na-emepụta ọkpọkọ ígwè. Alloy steel pipes bụkwa ihe dị mkpa maka ngwa agha dị iche iche. A na-eji ọkpọkọ ígwè rụọ orù égbè na orù. Alloy ígwè ọkpọkọ nwere ike kewaa gburugburu ọkpọkọ na pụrụ iche ekara ọkpọkọ dị iche iche cross-ngalaba shapes. Ebe ọ bụ na mpaghara okirikiri bụ nke kachasị ukwuu n'okpuru ọnọdụ nha anya, enwere ike ibufe mmiri karịa site na tube okirikiri. Tụkwasị na nke ahụ, mgbe a na-etinye akụkụ mgbanaka ahụ n'ime ma ọ bụ nrụgide radial, ike dị ntakịrị. Ya mere, ọtụtụ n'ime ọkpọkọ ígwè bụ ọkpọkọ gburugburu.

Nhazi nke ọkpọkọ alloy nwere mgbidi gbara ọkpụrụkpụ

Uru kachasị mma nke ọkpọkọ alloy nwere mgbidi bụ na enwere ike ịmegharị ha 100%, nke dabara na atụmatụ mba nke nchekwa gburugburu ebe obibi, ịzọpụta ike, na ịzọpụta akụrụngwa. Amụma mba na-akwado mgbasawanye nke mpaghara ngwa nke ọkpọkọ alloy nwere mgbidi gbara ọkpụrụkpụ.

Nyochaa usoro

Na-ekpo ọkụ na-agbagharị (extruded enweghị nkebi ígwè tube): gburugburu tube billet → kpo oku → ịkpọpu → atọ mpịakọta cross rolling, na-aga n'ihu na-atụgharị ma ọ bụ extrusion → tube mwepụ → nha (ma ọ bụ ibelata) → jụrụ oyi → billet tube → ịgbatị → Nnwale nrụgide mmiri (ma ọ bụ ntụpọ). nchọpụta) → akara → nkwakọba ihe.

Oyi adọtara (akpọrela) ọkpọkọ nchara na-enweghị nkebi: okirikiri tube billet → kpo oku → ịkpọpu → isi → annealing → pickling → oiling (ọla kọpa) → ọtụtụ ihe osise oyi (mgbagharị oyi) → billet tube → ọgwụgwọ okpomọkụ → ịgbatị → Nnwale nrụgide mmiri (nchọpụta ntụpọ) → akara → nkwakọba ihe.

1XXX alloy usoro dabere na aluminom dị ọcha.

2XXX Aluminom alloy nwere ọla kọpa dị ka ihe bụ isi alloying.

3XXX Aluminom alloy na manganese dị ka isi alloying element.

Titanium alloy tube iji: Titanium alloy tube bụ nke a na-ejikarị na ụgbọ elu. Ọ bụ ụdị alloy tube nke a na-eji eme ihe maka ụgbọ elu nwere ike siri ike na oke okpomọkụ.

4XXX Aluminom alloy na silicon dị ka isi alloying element.

5XXX Aluminom alloy na magnesium dị ka isi alloying element.

6XXX Aluminom alloy na magnesium na silicon dị ka isi ihe na-eme ka ọ bụrụ ihe na-emepụta ihe.

7XXX Aluminom alloy nwere zinc dị ka ihe bụ isi alloying.

Alloy tube arọ usoro:[((mpụta dayameta-mgbidi ọkpụrụkpụ)* ọkpụrụkpụ mgbidi]*0.02483=kg/m (arọ kwa mita)