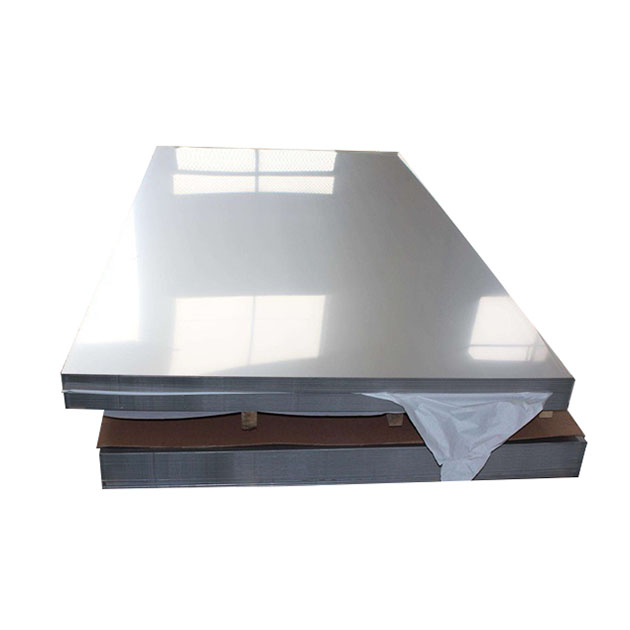

Ụlọ ọrụ na-ebunye nnukwu oyi na-atụ oyi mechaa efere mpempe akwụkwọ igwe anaghị agba nchara

Carbon (C): 1. Na-abawanye nguzogide nrụrụ na ike ike nke agụba;2. Mee ka ike sie ike ma melite nguzogide iyi.

Chromium (Cr): 1. Na-abawanye ike, ike ike na ike;2. Mgbochi iyi na corrosion.

Cobalt (Co): 1. na-abawanye ike na ike iguzogide oke okpomọkụ quenching;2. eji na ihe mgbagwoju anya alloys ike ụfọdụ onye Njirimara nke ndị ọzọ ọcha.

Ọla kọpa (Cu): 1. welie nguzogide corrosion;2. welie eyi nguzogide.

Manganese (Mn): 1. na-abawanye ike ike, na-eyi nguzogide na ike ike;2. na-ebupụ ikuku oxygen site na ígwè a wụrụ awụ site na-ekewapụ oxidation na ikewapụ vaporization;3. na-eme ka ike sie ike mana ọ na-abawanye brittleness ma ọ bụrụ na agbakwunyere ya na nnukwu ọnụọgụ.

Molybdenum (Mo):1. welie ike, ike, ike na ike;2. melite machinability na corrosion iguzogide.

Nickel (Ni): 1. welie ike, isi ike na nguzogide corrosion.

Phosphorus (P): kwalite ike, igwe na ike.

2. Ọ dị mfe ịgbaji na mgbawa mgbe itinye uche dị elu

Silicon (Si): 1. na-akwalite ductility;2. na-abawanye ike ike;3. na-ewepụ oxygen si na ọla a wụrụ awụ site na-ekewa oxidation na vaporization.

Sulfur (S): obere ego nwere ike imeziwanye machinability.

Tungsten (W): Mee ka ike, ike na isi ike.

Vanadium (V): Na-abawanye ike, isi ike na nguzogide ujo.

Mkpokọta nnyefe ọkụ nke igwe na-adabere na ihe ndị ọzọ na mgbakwunye na conductivity thermal nke metal.N'ọtụtụ ọnọdụ, ihe nkiri na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, akpụkpọ anụ nchara na ọnọdụ elu nke ígwè.Igwe anaghị agba nchara nwere ike idowe elu dị mma, ya mere, ọ ka mma karịa ọla ndị ọzọ na-enwe mmetụta okpomọkụ dị elu na nnyefe okpomọkụ.Liaocheng Sandeli igwe anaghị agba nchara na-enye asatọ, teknụzụ ụkpụrụ nke igwe anaghị agba nchara efere igwe anaghị agba nchara corrosion eguzogide, ekwe usoro arụmọrụ na welded akụkụ siri ike, yana welded akụkụ nke stamping usoro magburu onwe arụmọrụ nke elu-ike igwe anaghị agba nchara efere na mmepụta ya. usoro.Kpọmkwem, ọ nwere C: 0.02% ma ọ bụ obere, N: 0.02% ma ọ bụ obere, Cr: 11% ma ọ bụ karịa 17%, ọdịnaya kwesịrị ekwesị nke Si, Mn, P, S, Al, Ni, na izute 12 ≤ Cr Mo 1.5Si ≤ 17, 1 ≤ Ni 30 (CN) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3Mo ≥ 16.0, 0.006 ≤ CN ≤ 0.030 igwe anaghị agba nchara50 kpo oku na 1 igwe anaghị agba nchara50 ruo 1. ọgwụgwọ na ọnụego jụrụ oyi karịa 1 ℃ / s.Nke a nwere ike ịghọ nnukwu ike igwe anaghị agba nchara nwere ihe karịrị 12% nke akụkụ nke martensite nzukọ, karịa 730 MPa nke ike dị elu, nguzogide corrosion na ịgbado usoro, na ike siri ike na mpaghara ikpo ọkụ na-emetụta okpomọkụ.Mgbe ahụ jiri Mo, B, wdg, nwere ike imeziwanye akụkụ welded nke usoro stampụ nke ọma.

(1) Bridge ígwè efere;(2) efere igwe eji esi mmiri ọkụ;(3) efere ígwè na-arụ ụgbọ mmiri;(4) Ihe agha ígwè efere;(5) Ụgbọ ala ígwè efere;(6) Efere nchara nchara;(7) Efere nchara arụrụ arụ;(8) Efere igwe eletriki (akwụkwọ mpempe akwụkwọ silicon);(9) efere ígwè mmiri mmiri;(10) Efere pụrụ iche nke anyanwụ (Hai Rui nchara pụrụ iche);(11) Abụọ ndị ọzọ, nkịtị na n'ibu structural efere ígwè na nkịtị Japanese akara ule.

Mgbanwe ọkụ maka akụrụngwa maka pulp na akwụkwọ, igwe na akụrụngwa, ihe eji esiji ihe, ihe eji eme ihe nkiri, ọkpọkọ, ihe mpụga maka ụlọ dị n'akụkụ osimiri, wdg.

| Ọkwa | Ibu ibu | Ọkwa | Ibu ibu |

| lCrl7Mn6Mi5N | 7.93 | 3Crl3 | 7.75 |

| lCrl8MnBNiSN | 7.93 | 0Crl7Ni12M02 | 7.98 |

| lCrl7Ni7 | 7.93 | 00Crl7Nil4M02 | 7.98 |

| 1Crl7Ni8 | 7.93 | 0Cr17Ni12M02N | 7.98 |

| 1Crl8Ni9 | 7.93 | 00Crl7Nil2M02N | 7.98 |

| lCrl8Ni9Si3 | 7.93 | 0CrlSNil2M02Cu2 | 7.98 |

| OCrl9Ni9 | 7.93 | 00Crl8Nil4M02Cu2 | 7.98 |

| 00Crl9Nil l | 7.93 | 0Crl9Nil3M03 | 7.98 |

| 0Crl9Ni9N | 7.93 | 00Crl9Nil 3M03 | 7.98 |

| 00Crl 8NilON | 7.93 | 0Crl8Nil6M05 | 8.00 |

| 00Crl8Nil2 | 7.93 | 0Crl8Ni11Ti | 7.93 |

| 0Cr23Nil3 | 7.93 | OCrl8NillNb | 7.98 |

| 0Cr25Ni20 | 7.93 | 0Crl8Nil3Si4 | 7.75 |

| 00Crl7MO | 7.98 | 00crl8M02 | 7.75 |

| 7Crl7 | 7.70 | 00Cr30M02 | 7.64 |

| 0Cr26Ni5M02 | 7.70 | lCrl5 | 7.70 |

| lCrl2 | 7.80 | 3Crl6 | 7.70 |

| 0Crl3A1 | 7.7S | lCrl7 | 7.70 |

| 1Crl3 | 7.7S | OOCrl7 | 7.70 |

| OCrl3 | 7.75 | lCrl7Mo | 7.70 |

| OOCrl2 | 7.75 | 00Cr27Mo | 7.67 |

| 2Crl3 | 7.75 | 0Crl7N|7 Al | 7.93 |