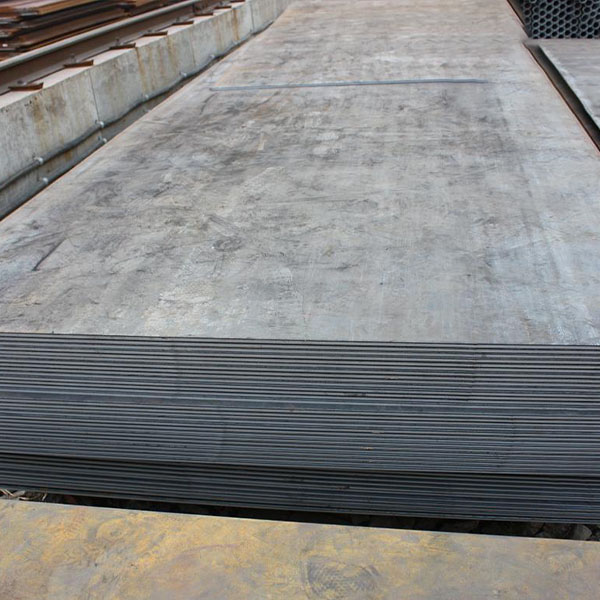

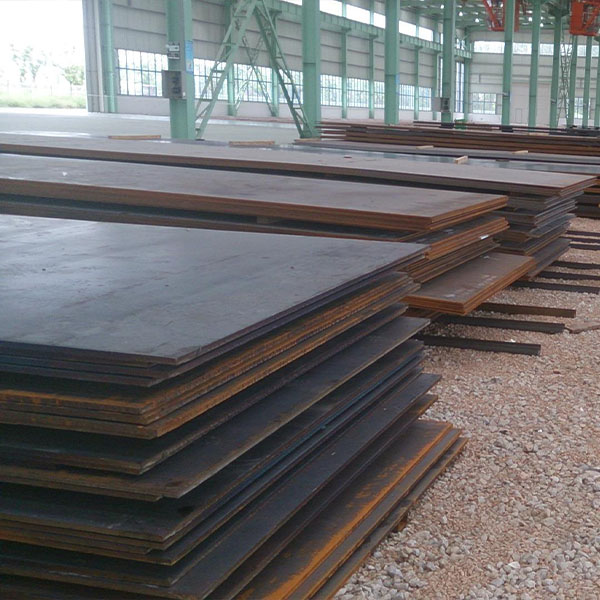

Obere Alloy ji esi mmiri ọkụ Steel efere

Obere alloy ígwè

A na-ekewa nchara nchara n'ime nchara dị ala, ọkara-alloy ígwè na elu-alloy ígwè. Dị ka aha ahụ na-egosi, a na-ekewa ha site na ngụkọta nke ihe ndị na-emepụta ihe. Ngụkọta ego bụ ihe na-erughị 3.5% a na-akpọ obere alloy ígwè, na 5-10% bụ ọkara alloy ígwè. Ihe karịrị 10% bụ nnukwu alloy ígwè. Na omenala ụlọ, carbon ígwè na alloy ígwè nke àgwà pụrụ iche na-akpọ ígwè pụrụ iche. Ụlọ ọrụ nchara 31 pụrụ iche n'ofe mba ahụ bụ ọkachamara n'ịmepụta ụdị ígwè a, dị ka ígwè arụ ọrụ carbon dị elu, ígwè arụ ọrụ alloy, ígwè ọrụ carbon, na ngwá ọrụ alloy. Igwe anaghị agba nchara, ngwa ngwa ngwa ngwa ngwa ngwa, carbon spring steel, alloy spring steel, bearing steel, igwe anaghị agba nchara, igwe anaghị agba nchara, igwe eletriki, gụnyere alloys okpomọkụ dị elu, alloys na-eguzogide corrosion na nkenke alloys, wdg.

jiri

A na-ejikarị emepụta àkwà mmiri, ụgbọ mmiri, ụgbọ ala, ndị na-ekpo ọkụ ọkụ, ụgbọ mmiri dị elu, mmanụ na mmanụ gas, nnukwu ígwè ígwè, wdg.

Arụmọrụ

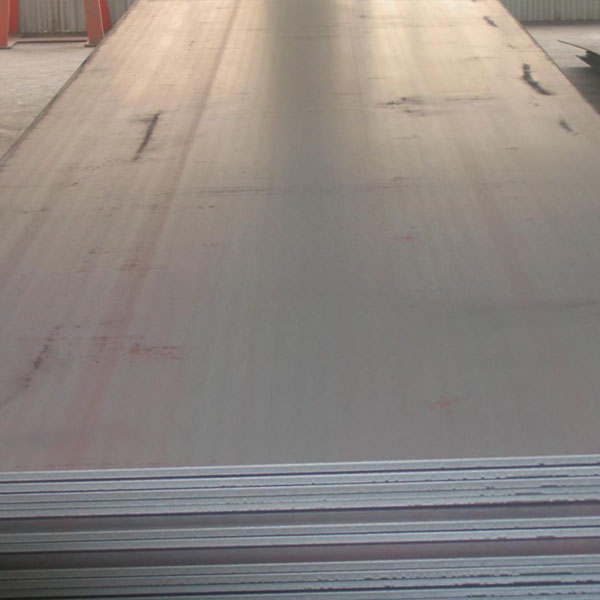

(1) Ike dị elu: N'ozuzu ike mkpụrụ ya dị n'elu 300MPa;

(2) Elu siri ike: A chọrọ elongation ka ọ bụrụ 15% -20%, na mmetụta okpomọkụ nke ime ụlọ dị elu karịa 600kJ / m ~ 800kJ / m. Maka nnukwu akụrụngwa welded, a na-achọkwa ike mgbaji dị elu;

(3) Ezi ịgbado ọkụ arụmọrụ na oyi akpụ arụmọrụ;

(4) Okpomọkụ mgbanwe oyi na-akụ obere oyi;

(5) Ezigbo nguzogide corrosion.

Laser ịkwa akwa-welded oghere na-aga n'ihu agbanwe cross-ngalaba osisi teknụzụ

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) na-eji laser dị ka isi iyi ọkụ ịgbado ọkụ iji jikọta na ịgbanye ọtụtụ ihe dị iche iche, ọkpụrụkpụ dị iche iche, na mkpuchi dị iche iche nke ígwè, igwe anaghị agba nchara, aluminum alloy, wdg n'ime efere dum.

2. Iji laser ahaziri ịgbado ọkụ technology, ọ ga-ekwe omume iji ezi uche na-ejikọta ihe nke dị iche iche ọkpụrụkpụ nha na ike ọkwa dị ka nrụgide ọnọdụ nke structural akụkụ, melite structural rigidity mgbe ibelata arọ nke akụkụ, na-amụba itinye n'ọrụ ọnụego. nke ihe ma belata ọnụ ọgụgụ nke akụkụ. Ọnụ ọgụgụ nke akụkụ na-eme ka usoro ahụ dị mfe. Teknụzụ ịgbado ọkụ laser ahaziri aghọọla ụzọ teknụzụ kachasị nke ụgbọ ala dị fechaa, etinyere ya na ụdị nke ọtụtụ ndị nrụpụta. A na-eji ya eme ihe n'ihu na azụ ọnụ ụzọ ime n'ime, ihu na azụ ogologo ogologo, akụkụ akụkụ, ogwe ala, A, B, na C ogidi n'ime ọnụ ụzọ ahụ, mkpuchi wiil na ogwe dị n'ime, wdg.

3. Tailor Rolling Blanks (TRB), nke a na-akpọkwa efere dị iche iche, na-ezo aka na ngbanwe nke oge mpịakọta mpịakọta site na kọmputa n'oge usoro mpịakọta nke efere ígwè, nke mere na efere ahụ a na-atụgharị nwere tupu ekpebie ya. uzo n'akuku uzo uzo. Omenala mgbanwe n'ụdị obe.

4. Na-aga n'ihu mgbanwe cross-ngalaba panel technology e ọtụtụ-eji na-emepụta nke ahu Ọdịdị akụkụ, dị ka engine cover, B-ogidi, body chassis, moto spacer ndu, n'etiti kọlụm n'ime panel, mudguard na okuku igbe, wdg. na etinyere ya nke ọma na Audi, BMW, Volkswagen, GM na ụdị ndị ọzọ.

5. Laser ahaziri ịgbado ọkụ na-aga n'ihu agbanwe cross-ngalaba technology na-agbanwe ọkpụrụkpụ nke stamping ihe site dị iche iche na nkà na ụzụ n'ụzọ, na-eji na-edozi nsogbu nke dị iche iche ibu-ebu ikike chọrọ n'ihi na dị iche iche nke akpaaka akụkụ n'okpuru ibu. N'iji ya tụnyere abụọ, uru nke ịkwa akwa-mere laser ịgbado ọkụ technology dabeere ya mgbanwe, nke nwere ike na-aghọta splicing nke ọ bụla ọnọdụ na splicing nke dị iche iche ihe. The uru nke na-aga n'ihu agbanwe cross-ngalaba technology bụ na ọ dịghị ịgbado ọkụ onuete, ekweghị ekwe mgbanwe n'akụkụ ogologo direction bụ dịtụ nwayọọ, ọ nwere mma formability, na elu àgwà dị mma, mmepụta arụmọrụ dị elu, na-eri bụ. ala. Akpa, akụrụngwa ahụike, shei ọgba tum tum; ụgbọ ala, ụgbọ ala ime ụlọ, dashboard; nkwado oche, ogwe ọnụ ụzọ, windo windo, wdg.