Igwe ọkụ akpọrepu enweghị nha nha nha

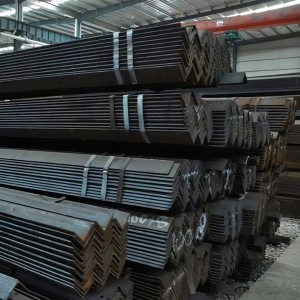

Edebere ogo elu nke nchara nchara na-enweghị nha n'usoro, na a na-achọkarị ka ọ ghara inwe ntụpọ na-emerụ ahụ dị ka delamination, scarring, na cracks.

The allowable nso nke geometric udi deviation nke unequal n'akuku ígwè bụkwa kpọmkwem na ọkọlọtọ, nke n'ozuzu na-agụnye ihe ndị dị ka curvature, akụkụ obosara, akụkụ ọkpụrụkpụ, n'elu akụkụ, theoretical arọ, wdg, na-akọwa na unequal n'akuku ígwè agaghị enwe. torsion dị ịrịba ama

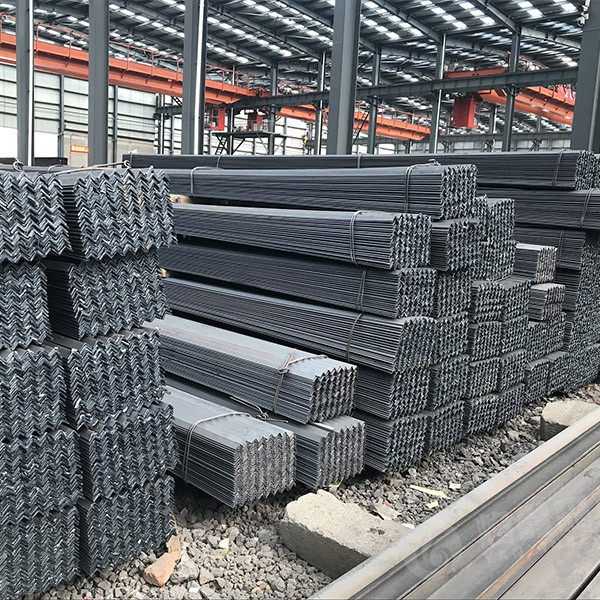

GB/T2101-89 (Nkwadebe zuru oke maka nnabata nchara, nkwakọ ngwaahịa, akara na asambodo mma); GB9787-88/GB9788-88 (na-ekpo ọkụ na-ekpo ọkụ equilateral/ unaquilateral n'akuku ígwè size, udi, arọ na ekwe ndiiche); JISG3192- 94 (ọdịdị, nha, ịdị arọ na ndidi nke nchara na-ekpo ọkụ na-ekpo ọkụ); DIN17100-80 (ụkpụrụ dị mma maka nchara nhazi nkịtị); ГОСТ535-88 (onodu teknụzụ maka akụkụ carbon nkịtị).

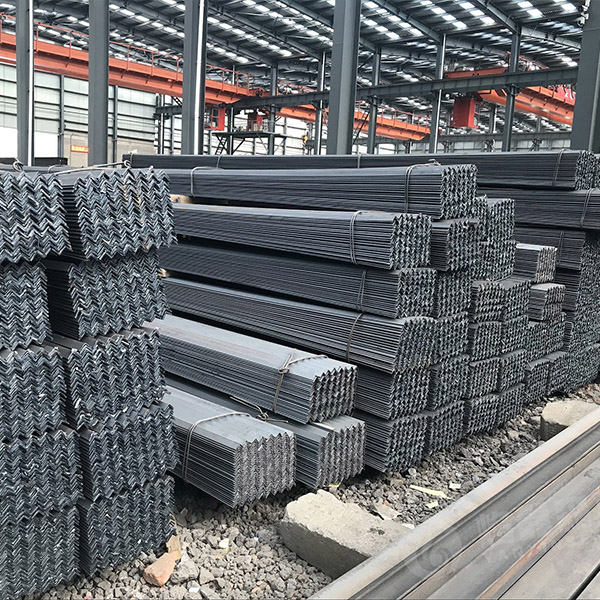

Dị ka ụkpụrụ ndị a kpọtụrụ aha n'elu, a ga-enyefe akụkụ ndị na-enweghị isi na ngwugwu, na ọnụ ọgụgụ nke ngwugwu na ogologo nke otu ngwugwu ga-agbaso ụkpụrụ. A na-ebufe nchara nchara na-enweghị nha anya n'ozuzu ya, ọ dịkwa mkpa ịṅa ntị na mmiri na-egosi n'oge njem na nchekwa.

A na-eji ya n'ọtụtụ ebe n'ọtụtụ obodo dị iche iche, ihe owuwu obodo na ihe owuwu ụlọ ọrụ agha na ụlọ ọrụ injinia, dị ka osisi ụlọ ọrụ mmepụta ihe, àkwà mmiri, ụlọ ọrụ nnyefe ike, igwe na-ebuli na ibu, ụgbọ mmiri, ọkụ ụlọ ọrụ, ụlọ nrụpụta mmeghachi omume, igbe nkwakọba ihe, na ụlọ nkwakọba ihe. wdg, n'ihi na oriri ha erughị nchara n'akụkụ otu akụkụ, ọnụ ahịa ndị ikwu dị ntakịrị elu.

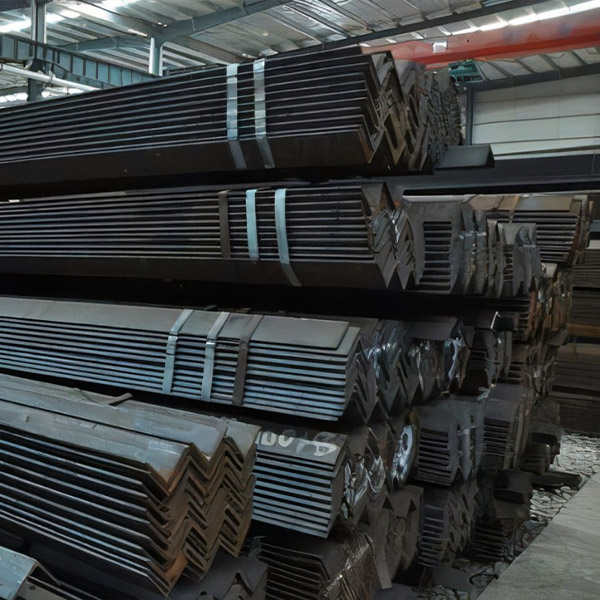

1. Ọnụ ego nhazi dị ala: ọnụ ahịa galvanizing na-ekpo ọkụ na mgbochi nchara dị ala karịa nke mkpuchi agba ndị ọzọ;

2. Inogide na inogide: Hot-mikpu galvanized n'akuku ígwè nwere àgwà nke elu gloss, edo zinc oyi akwa, ọ dịghị leakage plating, dịghị dripping, ike adhesion, na ike corrosion iguzogide. Na gburugburu ime obodo, ọkọlọtọ na-ekpo ọkụ-mikpu galvanizing mgbochi nchara nwere ike ịnọgide na-enwe ihe karịrị afọ 50 na-enweghị ịrụzi; n'ime obodo ma ọ bụ mpaghara dịpụrụ adịpụ, enwere ike idobe oyi akwa mgbochi corrosion na-ekpo ọkụ na-ekpo ọkụ ruo afọ 20 na-enweghị ịrụzi;

3. Ezi ntụkwasị obi: Igwe galvanized na nchara na-ejikọta ya na metallurgical ma ghọọ akụkụ nke nchara nchara, n'ihi ya, ogologo oge nke mkpuchi ahụ bụ ihe a pụrụ ịdabere na ya;

4. Ihe mkpuchi ahụ nwere ike siri ike: mkpuchi zinc na-eme ka ọkpụkpụ metallurgical pụrụ iche, nke nwere ike iguzogide mmebi usoro n'oge njem na ojiji;

5. Nchedo zuru oke: akụkụ ọ bụla nke akụkụ ahụ nwere ike iji zinc kpuchie ya, ọbụnadị na nkwụsịtụ, akụkụ dị nkọ na ebe zoro ezo nwere ike ichebe nke ọma;

6. Ịchekwa oge na ịzọpụta ọrụ: usoro galvanizing na-adị ngwa ngwa karịa ụzọ ndị ọzọ na-ewu mkpuchi mkpuchi, ọ pụkwara izere oge a chọrọ maka eserese na ebe a na-ewu ụlọ mgbe echichi gasịrị.

Galvanized n'akuku ígwè na ọtụtụ-eji ike ụlọ elu, nkwurịta okwu ụlọ elu, ákwà mgbochi mgbidi ihe, shelf ewu, ụgbọ okporo ígwè, okporo ụzọ nchebe, okporo ụzọ ìhè okporo osisi, mmiri mmiri, ụlọ ígwè structural components, substation ancillary ụlọ ọrụ, ìhè ụlọ ọrụ, wdg.