Efere igwe anaghị agba nchara na-ekpo ọkụ

A na-achọrọ ka ọ nwee ike iguzogide corrosion nke oxalic acid, sulfuric acid iron sulfate, nitric acid, nitric acid hydrofluoric acid, sulfuric acid ọla kọpa sulfate, phosphoric acid, formic acid, acetic acid na acid ndị ọzọ. A na-ejikarị ya eme ihe na ụlọ ọrụ kemịkalụ, nri, ọgwụ, imepụta akwụkwọ, mmanụ ala, ike atomiki na ụlọ ọrụ ndị ọzọ, yana akụkụ dị iche iche nke ụlọ, kichin kichin, tebụl, ụgbọ ala na ngwa ụlọ. Iji hụ na ihe ndị na-emepụta ihe dị ka ike mkpụrụ, ike nkwụsị, elongation na hardness nke dị iche iche igwe anaghị agba nchara na-emezu ihe ndị a chọrọ, efere ígwè ga-enweta ọgwụgwọ okpomọkụ dị ka nkwụsịtụ, ọgwụgwọ ngwọta na ọgwụgwọ ịka nká tupu nnyefe.

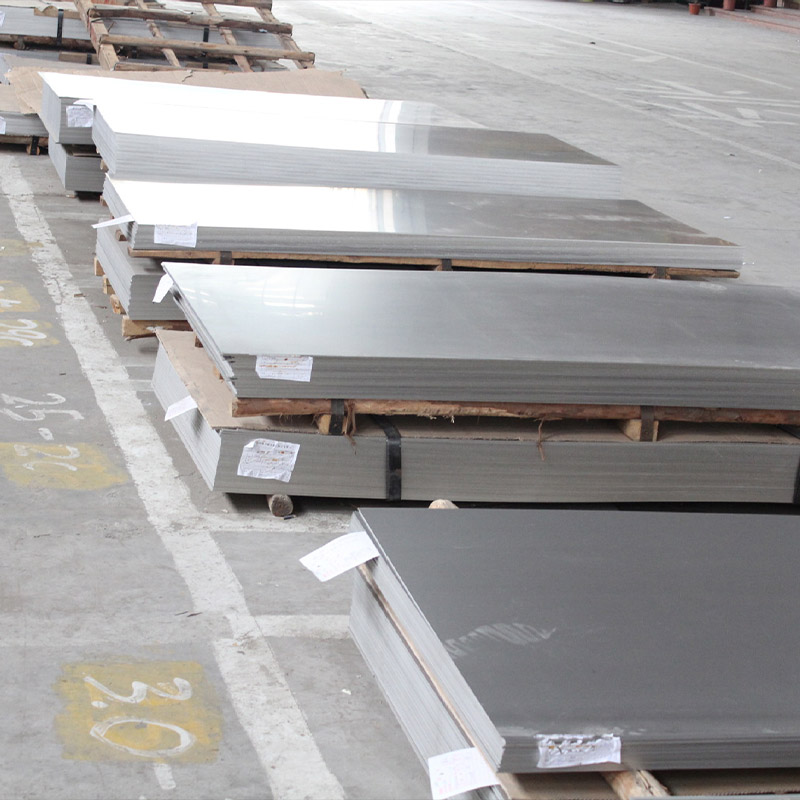

Efere igwe anaghị agba nchara nwere elu dị larịị, nnukwu plasticity, ike siri ike na ike n'ibu, ma na-eguzogide corrosion nke acid, alkaline gas, ngwọta na mgbasa ozi ndị ọzọ. Ọ bụ ụdị alloy ígwè na-adịghị mfe nchara, ma ọ bụghị kpamkpam nchara.

The corrosion eguzogide nke igwe anaghị agba nchara tumadi dabere na ya alloy mejupụtara (chromium, nickel, titanium, silicon, aluminum, wdg) na esịtidem Ọdịdị. Chromium na-arụ nnukwu ọrụ. Chromium nwere nkwụsi ike nke kemịkalụ dị elu, nwere ike ịmepụta ihe nkiri na-agafe agafe n'elu igwe, kewapụ ígwè ahụ n'èzí, chebe efere ígwè site na oxidation ma mee ka nkwụsị nke corrosion nke efere ígwè dị elu. Mgbe e bibisịrị ihe nkiri passivation, nguzogide corrosion na-ebelata.

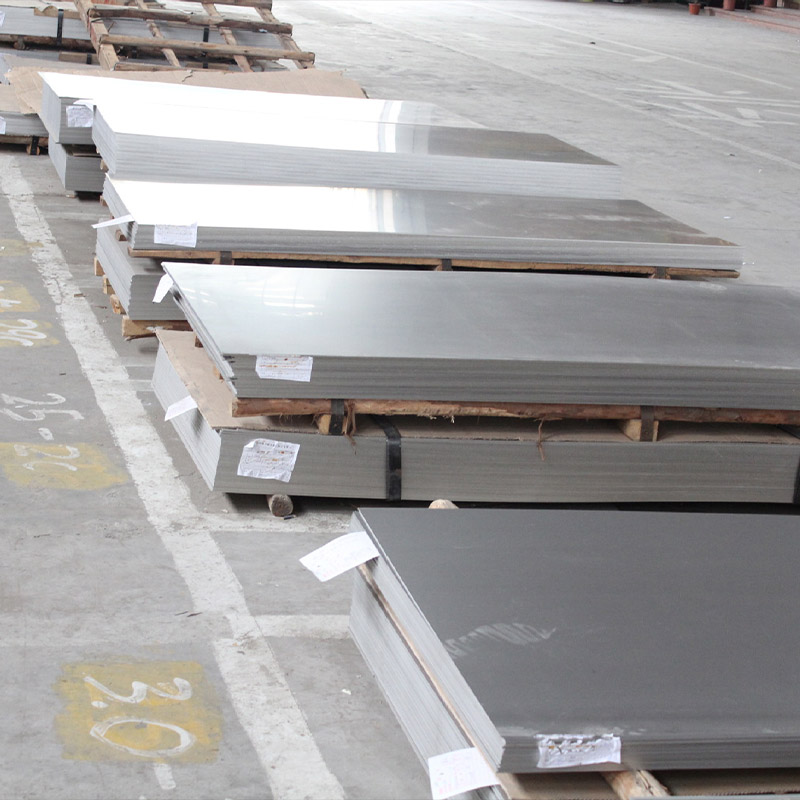

Dị ka usoro nrụpụta si dị, enwere ụdị abụọ nke ịgbagharị ọkụ na ntụgharị oyi, gụnyere efere dị nro nke nwere ọkpụrụkpụ nke 0.5-4 mm na nnukwu efere nwere ọkpụrụkpụ nke 4.5-35 mm.

Dabere na njirimara nhazi nke ọkwa nchara, enwere ike kewaa ya na ụdị 5: ụdị austenite, ụdị austenite ferrite, ụdị ferrite, ụdị martensite na ụdị mmiri ozuzo.

High ike igwe anaghị agba nchara efere na magburu onwe corrosion eguzogide, ekwe processability na toughness nke ịgbado ọkụ akụkụ, nakwa dị ka stamping processability nke ịgbado ọkụ akụkụ na ya n'ichepụta usoro. Kpọmkwem, efere igwe anaghị agba nchara nwere Si, Mn, P, s, Al na Ni nwere ọdịnaya kwesịrị ekwesị na-erughị 0.02% nke C, ihe na-erughị 0.02% nke N, karịa 11% nke Cr na ihe na-erughị 17%, na imezu ihe achọrọ nke 12 ≤ Cr Mo 1.5si ≤ 17, 1 ≤ Ni 30 (cn) 0.5 (Mn) Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3mo ≥ 16.0, 0.006 ≤ C n ≤ 0.030 ga-ekpo ọkụ na 850 ~ 1250 ℃, na mgbe ahụ, a ga-eme ọgwụgwọ okpomọkụ na ọnụego jụrụ oyi karịa / 1 ℃. s. N'ụzọ dị otú a, ọ nwere ike ịghọ a elu-ike igwe anaghị agba nchara efere na martensite ọdịnaya nke karịa 12% site olu, elu ike karịa 730mpa, corrosion eguzogide na ekwe processability, na magburu onwe ike nke ịgbado ọkụ okpomọkụ emetụtara mpaghara. Enwere ike imeziwanye arụmọrụ stampụ nke akụkụ welded site na iji Mo, B, wdg.