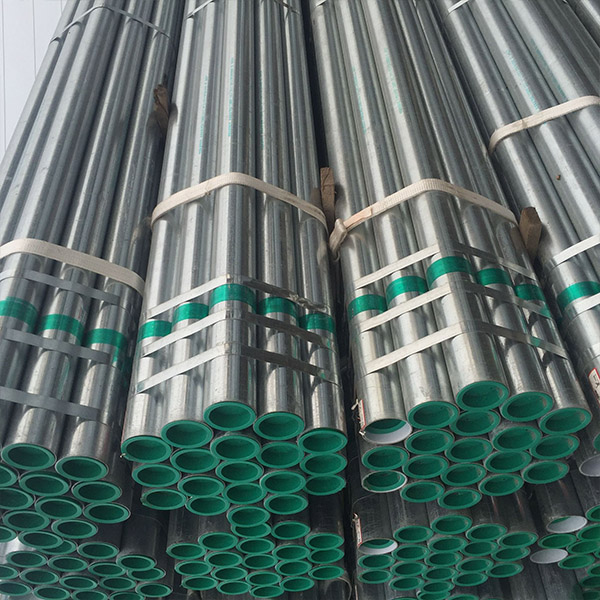

Ọkụ Galvanized

Usoro usoro bụ:nwa tube-alkaline ịsacha-mmiri na-asachapụ-mmiri na-ekpochapụ-mmiri ihe enyemaka-ịkụcha-ọkụ na-ekpo ọkụ galvanizing-mpụpụ ịfụ n'ime ime-ikuku jụrụ oyi-mmiri jụrụ oyi - Passivation-mmiri rinsing-nyocha-nchekwa-atụ.

1, Brand na chemical mejupụtara

Ọkwa na ihe mejupụtara kemịkalụ nke ígwè maka ọkpọkọ ígwè galvanized kwesịrị ịgbaso ọkwa ọkwa na kemịkalụ nke ígwè maka ọkpọ ojii dị ka akọwapụtara na GB / T3091.

2, Usoro nrụpụta

A na-ahọrọ usoro nrụpụta nke ọkpọkọ ojii (ọkụ ọkụ ma ọ bụ ịgbado ọkụ eletrik) site na onye nrụpụta. A na-eji galvanizing na-ekpo ọkụ na-ekpo ọkụ eme ihe.

3. Njikọ eriri na ọkpọkọ

(a) N'ihi na galvanized ígwè ọkpọkọ na-ebunye na eri, eri kwesịrị machined mgbe galvanized. Eriri kwesịrị ịgbaso ụkpụrụ YB 822.

(b) Njikọ ọkpọ ígwè kwesịrị ịgbaso YB 238; Njikọ ọkpọkọ nke nkedo nke nwere ike ime ka ọ bụrụ YB 230.

4. Mechanical Njirimara The n'ibu Njirimara nke ígwè ọkpọkọ tupu galvanizing kwesịrị izute chọrọ nke GB 3091.

5. Uniformity nke galvanized oyi akwa Galvanized ígwè ọkpọkọ kwesịrị ịnwale maka ịdị n'otu nke akwa akwa galvanized. Ihe atụ nke ọkpọkọ ígwè agaghị atụgharị uhie (ọla kọpa) mgbe etinyere ya na ngwọta sulfate ọla kọpa maka oge 5 n'usoro.

6, Cold ehulata ule galvanized ígwè anwụrụ na a nominal dayameta nke bụghị ihe karịrị 50mm kwesịrị oyi ekwe ule. Nkuku na-ehulata bụ 90º, na radius na-ehulata bụ okpukpu 8 nke mpụta. Enweghị ihe nkpuchi n'oge ule ahụ, a ga-etinyekwa weld nke ihe nlele ahụ n'èzí ma ọ bụ akụkụ elu nke ntụziaka na-ehulata. Mgbe ule ahụ gasịrị, ọ dịghị ihe mgbawa na peeling nke oyi akwa zinc na sample.

7, Nnwale nrụgide mmiri Ekwesịrị ịme ule nrụgide mmiri na clarinet, a pụkwara iji ule eddy ugbu a mee ihe kama ịnwale ule mmiri. Nnwale ule ma ọ bụ nha nke ihe atụ atụnyere maka ule eddy ugbu a ga-ezute ihe ndị chọrọ GB 3092. Ngwá ọrụ ígwè ọrụ nke ígwè bụ ihe ndị dị mkpa na-egosi iji hụ na arụmọrụ ikpeazụ (mechanical Properties) nke ígwè.

① Ike nkwụsị (σb):Oke kachasị ike (Fb) nke ihe nlele ahụ na-agbaji mgbe ọ na-agbaji n'oge usoro ịgbatị ahụ, kewara site na nrụgide (σ) nwetara site n'ịkewa ebe mbụ cross-section (So) nke ihe atụ, a na-akpọ ike nkwụsị ike (σb). , unit bụ N/mm2 (MPa). Ọ na-anọchi anya ike kachasị nke ihe igwe na-eguzogide mmebi n'okpuru ike nkwụsị. N'ime usoro: Fb - ike kachasị nke ihe nlele na-agbaji mgbe ọ gbajiri, N (Newton); Ya mere-mbụ cross-ngalaba nke sample, mm2.

② Ọnụ mkpụrụ (σs):Maka ihe igwe na-emepụta ihe na-emepụta ihe, nchekasị nke ihe nlele ahụ nwere ike ịga n'ihu na-agbatị n'ebughị ibu n'oge usoro ịgbatị a na-akpọ ebe mkpụrụ. Ọ bụrụ na ike daa, a ga-amata isi ihe dị elu na nke ala. Otu nkeji mkpụrụ bụ N/mm2 (MPa). Upper Mpụta Point (σsu): Nchegbu kachasị tupu ihe atụ a na-amịpụta na ike na-adaba maka oge mbụ; Obere Mpụta Mpụta (σsl): Opekempe nchekasị dị na ọkwa mkpụrụ mgbe etinyeghị mmetụta mbido mbụ. Ebe: Fs--mkpụrụ ike (mgbe niile) n'oge usoro nkwụsị nke ihe nlele, N (Newton) Ya mere - ebe mbụ cross-section nke sample, mm2.

③ Elongation mgbe agbajichara:(σ) N'ime ule nyocha, pasent nke ogologo nke ogologo nlele ahụ mụbara mgbe e mebisịrị ihe nlele ahụ na ogologo nlele mbụ a na-akpọ elongation. Kwuru site na σ, nkeji ahụ bụ%. Na usoro: L1-nlele ogologo nke ihe atụ mgbe agbajisịrị, na mm; L0 - ogologo nlele izizi nke ihe nlere, na mm.

④ Mbelata mpaghara:(ψ) N'ime ule nyocha, a na-akpọ pasent nke oke mbelata nke mpaghara obe na mbelata nke ntanye nke ihe nlele ahụ mgbe a na-agbaji ihe nlele ahụ na mpaghara nke mbụ na-akpọ mbelata nke mpaghara. Ekwuru na ψ, unit ahụ bụ%. Na usoro: S0-mbụ cross-section mpaghara nke sample, mm2; S1-nke kacha nta n'ofe akụkụ na dayameta mbelata nke ihe nlele mgbe agbajichara ya, mm2.

⑤ Ndekọ isi ike:A na-akpọ ike nke ihe ígwè iji gbochie ntinye nke ihe siri ike n'elu ala. Dị ka usoro ule dị iche iche na ngwa ngwa si dị, enwere ike kewaa ike ike n'ime brinell hardness, Rockwell hardness, Vickers hardness, Shore hardness, micro hardness na high okpomọkụ hardness. Enwere ọkpọkọ atọ a na-ejikarị: Brinell, Rockwell, na Vickers hardness.

hardness brinell (HB):Jiri bọọlụ nchara ma ọ bụ bọọlụ cemented carbide nwere otu dayameta ka ịpịnye ya n'elu ihe nlele ya na ike nnwale akọwapụtara (F), wepụ ike nnwale ahụ mgbe oge ejidere akọwapụtara, wee tụọ dayameta ntinye n'elu n'elu. sample (L). The Brinell hardness uru bụ quotient enwetara site na-ekewa ule ike site okirikiri elu ebe nke indentation. Egosiputara ya na HBS (bọọlụ igwe), nkeji ahụ bụ N/mm2 (MPa).