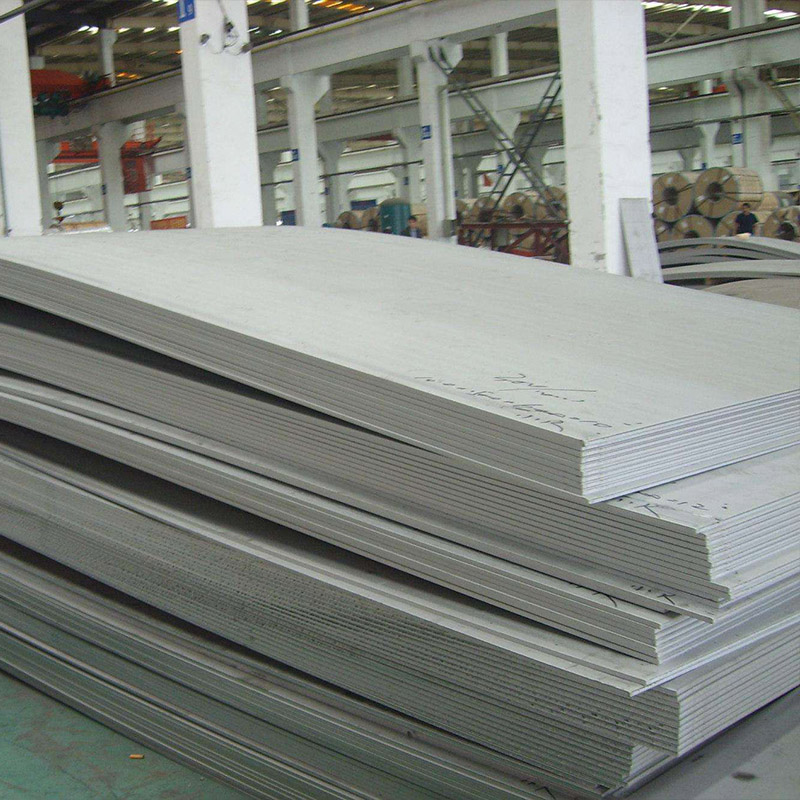

304 igwe anaghị agba nchara efere

Ọkwa: 300 usoro

ọkọlọtọ: ASTM

Ogologo: Omenala

Ọkpụrụkpụ: 0.3-3mm

Obosara: 1219 ma ọ bụ omenala

Mmalite: Tianjin, China

Aha aha: jinbaicheng

Ụdị: igwe anaghị agba nchara

Ụdị: mpempe akwụkwọ, mpempe akwụkwọ

Ngwa: ịcha akwa na ịchọ mma nke ụlọ, ụgbọ mmiri na ụzọ ụgbọ oloko

Ndigide: ± 5%

Ọrụ nhazi: ịgbado, ịgbado ọkụ, uncoiling, ịkụ ọkpọ na ịkpụ

Ọkwa ígwè: 301L, s30815, 301, 304n, 310S, s32305, 410, 204c3, 316Ti, 316L, 34,14j 321, 410S, 410L, 436l, 310L, 436L, 436L, 310L 314, 347, 430, 309S, 304, 439, 204c2, 425m, 409L, 4, 5, 30L, 4, 5, 30j2 444, 301LN, 305, 429, 30

Ọgwụgwọ dị n'elu: BA

Oge nnyefe: 8-14

Aha ngwaahịa: 304 igwe anaghị agba nchara

Usoro: ntụgharị oyi na ntụgharị ọkụ

Elu: Ba, 2b, No.1, no.4,8k, HL,

N'ọnụ mirror: egweri na trimming

Nkwakọ ngwaahịa: ihe nkiri PVC + akwụkwọ enweghị mmiri + osisi osisi fumigation

Ọmụma: free sample

430 igwe anaghị agba nchara bụ nchara n'ozuzu nwere ezigbo nguzogide corrosion. Ya thermal conductivity dị mma karịa nke austenite, ọnụ ọgụgụ ya nke thermal mgbasawanye dị nta karịa nke austenite, okpomọkụ ike ọgwụgwụ na-eguzogide, mgbakwunye nke stabilizing element titanium, na ezi n'ibu Njirimara na weld. A na-eji igwe anaghị agba nchara 430 mee ihe ịchọ mma ụlọ, akụkụ ọkụ ọkụ, ngwa ụlọ na ngwa ụlọ. 430F bụ ụdị nchara na-arụ ọrụ ịkpụ n'efu na ígwè 430. A na-ejikarị ya maka lathes akpaka, bolts na mkpụrụ. 430lx na-agbakwụnye Ti ma ọ bụ Nb na 430 ígwè ma na-ebelata ọdịnaya nke C, nke na-eme ka ọrụ nhazi na ịgbado ọkụ dịkwuo mma. A na-ejikarị ya na tank mmiri ọkụ, usoro inye mmiri ọkụ, ngwa ihe ọcha, ngwa ụlọ na-adịgide adịgide, ụgbọ elu igwe, wdg.

Ọkwa elu

430 igwe anaghị agba nchara nwere steeti ndị a. Steeti dị iche iche, nguzogide unyi na nguzogide corrosion dịkwa iche.

No.1, 1D, 2D, 2b, N0.4, HL, Ba, mirror, na ndị ọzọ dị iche iche n'elu ọgwụgwọ na-ekwu.

Nkà na ụzụ nhazi njirimara

1D - elu granular na-akwụsị, nke a makwaara dị ka elu elu. Nkà na ụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + mgbakasị ahụ, ịgbanye peening na pickling + oyi na-atụgharị + mgbakasị na pickling.

2D - ọla ọcha na-acha ọcha dị ntakịrị. Nkà na ụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + mgbakasị ahụ, ịgbanye peening na pickling + oyi na-atụgharị + mgbakasị na pickling.

2B - silvery ọcha na mma gloss na flatness karịa 2D elu. Nkà na ụzụ na-ahazi: ịgbagharị ọkụ na-ekpo ọkụ + ịhịa aka n'ahụ, ịgbanye peening na pickling + oyi na-agbagharị + mgbakasị ahụ na pickling + quenching na mkpụgharị iwe.

BA - ọmarịcha elu gloss na elu reflectivity, dị ka elu nke enyo. Teknụzụ na-arụ ọrụ: ịgbagharị ọkụ na-ekpo ọkụ + ịhịa aka n'ahụ, ịgba mgbọ na-atụgharị na ịtụgharị + oyi na-atụgharị + mgbakasị ahụ na pickling + polishing elu + na-emenyụ na mkpụgharị iwe.

NO.3 - ọ nwere ezigbo gloss na ọka na-enweghị isi n'elu. Nhazi teknụzụ: polishing na quenching na tempering Rolling nke 2D ngwaahịa ma ọ bụ 2B na 100 ~ 120 abrasive ihe (JIS R6002).

NO.4 - ọ nwere ezigbo gloss na ahịrị dị mma n'elu. Nhazi teknụzụ: polishing na quenching na tempering Rolling nke 2D ma ọ bụ 2B na 150 ~ 180 abrasive ihe (JIS R6002).

HL - ọlaọcha isi awọ na ntutu isi. Nhazi teknụzụ: Polish 2D ma ọ bụ 2B ngwaahịa na abrasive ihe na kwesịrị ekwesị urughuru size ime ka elu show na-aga n'ihu egweri ahịrị.

Mirro - mirror steeti. Nhazi teknụzụ: Mike na Polish 2D ma ọ bụ 2B ngwaahịa na kwesịrị ekwesị urughuru size egweri ihe na mirror mmetụta.

430 igwe anaghị agba nchara nwere ikike nke oxidation iguzogide corrosion, ma nwere ọchịchọ nke intergranular corrosion.

A na-eji waya igwe anaghị agba nchara 430 na axis.

N'ihi na ọ dị mma na nke na-adịghị egbu egbu, a na-ejikarị ya eme ihe na tebụl nri.

austenite

301,302, 303, 303se, 304, 304L, 304N1, 304N2, 304LN, 305, 309S, 310S, 316, 316L, 316N, 316J1, 316J1L, 316J1, 316J1L,37 321, 347, XM7, XM15J1, 329J1

Ferrite

405, 430, 430F, 434, 447J1, 403

Martensite

410, 410L, 405, 416, 410J1, 420J1, 420J2, 420F, 431, 440A, 440B, 440C, 440F, 630, 631, 632

E nwekwara ụdị igwe anaghị agba nchara, 201, 202, 203 na 204, nke nwere obere chromium na nnukwu manganese (ike chromium dị elu na-abawanye nguzogide corrosion, na manganese dị elu nwere ike ime ka ihe ahụ ghara ịdị na-eme ihe). Ụdị igwe anaghị agba nchara anaghị eguzogide corrosion na-ejikarị eme ihe maka ịchọ mma gburugburu ebe akọrọ.

| Elu | Atụmatụ | Nchịkọta nke ụzọ nrụpụta | Ebumnuche |

| NO.1 | Matte ọcha ọla ọcha | Na-ekpo ọkụ akpọrepu ruo kpọmkwem ọkpụrụkpụ | Jiri na-enweghị gloss elu |

| NO.2D | Ọcha ọcha | Okpomọkụ ọgwụgwọ na pickling mgbe oyi tụgharịa | Ihe n'ozuzu, ihe osise miri emi |

| NO.2B | Gloss siri ike karịa No.2D | Mgbe ọgwụgwọ No.2D gasịrị, a na-emegharị ọkụ oyi ikpeazụ site na igwe na-egbuke egbuke | Osisi n'ozuzu |

| BA | Na-egbuke egbuke dị ka enyo | Enweghị ọkọlọtọ, mana ọ na-abụkarị nhazi elu annealed na-egbuke egbuke, na-egosipụta elu elu. | Ihe owuwu ụlọ, arịa kichin |

| NO.3 | Na-egweri siri ike | Jiri eriri abrasive 100 ~ 200 # gwerie | Ihe owuwu ụlọ, arịa kichin |

| NO.4 | Egweri etiti | A na-egbu maramara elu nwetara site na-egweri na 150 ~ 180 # abrasive teepu | Otú ọ dị |

| NO.240 | Egweri nke ọma | Na-egweri na 240 # abrasive belt | ngwa nri |

| NO.320 | Iri nri nke ọma | Na-egweri na 320 # abrasive belt | Otú ọ dị |

| NO.400 | Gloss nso ba | Jiri wheel 400# polishing gwerie | Ihe eji eme ihe n'ozuzu, ihe owuwu ulo, arịa kichin |

| HL | Ntutu ahịrị egweri | Enwere ọtụtụ irighiri ihe na-egweri na ahịrị ntutu isi (150 ~ 240#) nwere akụrụngwa kwesịrị ekwesị. | Ihe owuwu ụlọ |

| NO.7 | Na nso enyo egweri | Na-egweri na 600 # rotary polishing wheel | Maka nka na ịchọ mma |

| NO.8 | Egweri enyo | Ngosipụta a na-eji wheel na-egbuke egbuke kpụrụ akpụ | Reflector, ịchọ mma |